One of the pioneers in the production and design of printed circuit boards. We are constantly driven to keep up with the fast-paced evolution of technology. China’s PCB board manufacturers are primarily concerned with mass manufacturing. However, the PCB facility has recently been upgraded with the most up-to-date technology to satisfy the demands of public. and other organizations. Take help of China PCB manufacturer to get the best prototype for your electronic gadgets at relevant prices.

In addition, the following upgrading equipment is available:

- Fully automated inspection equipment

- CNC Drilling Machine Etching Line

- Line of Automatic Optical Inspection

- Production line for electroplating

- Line of Exposure Machines

- Machine for forming

- Sink line made of copper

PCB manufacturing and service types which you should know: –

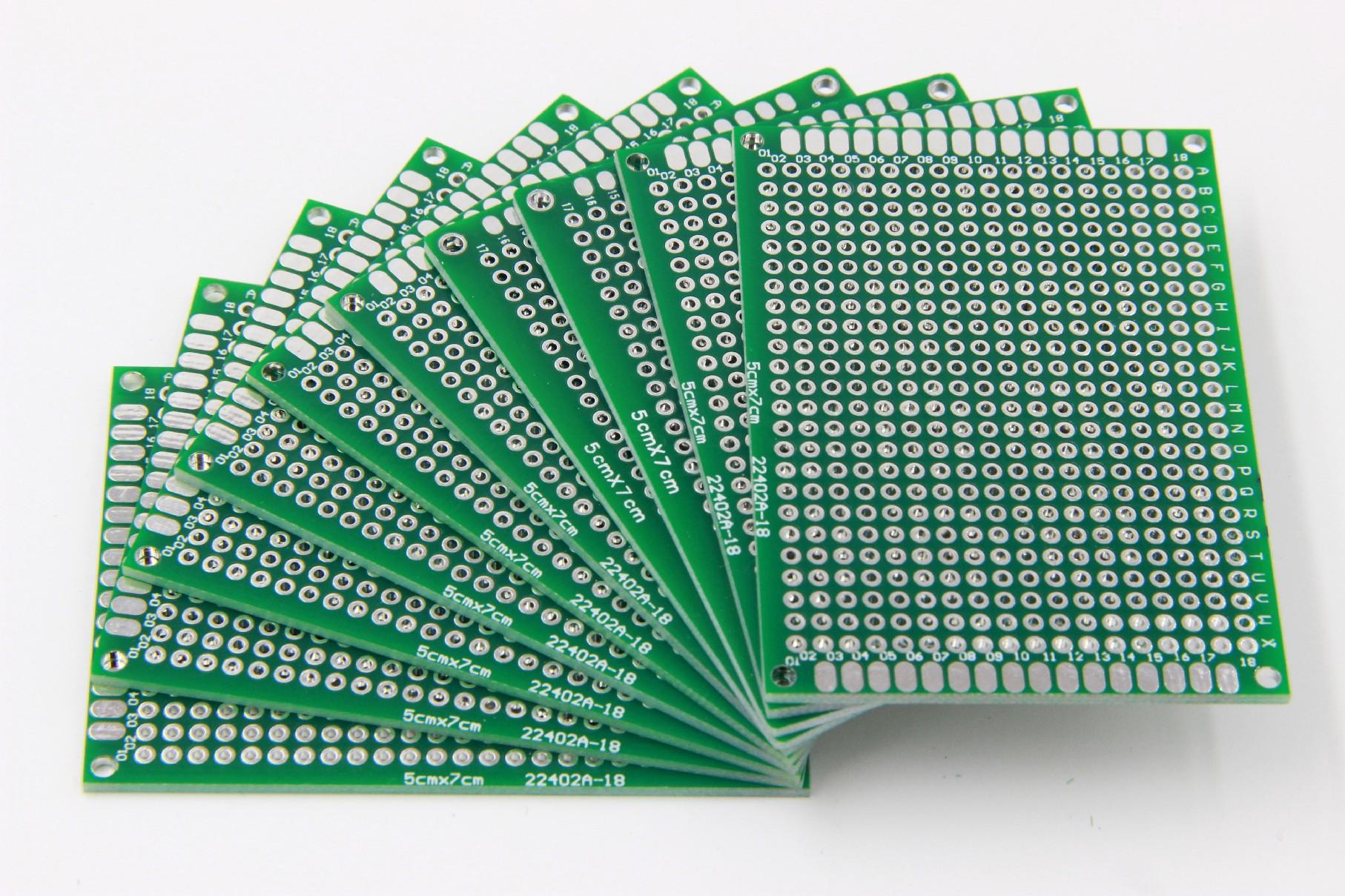

Single-sided PCB: –

Single-layer PCB is another name for it. It’s a circuit board with a base or substrate’s surface. They are pretty popular among hobbyists, and their manufacture is straightforward and inexpensive. As a result, it is appropriate. All components and pieces are arranged on one end of the device when single-sided. On the other hand, these boards are pretty valuable for basic electronics. They indicate limitations in complicated tasks.

PCB with Aluminum Backing: –

Because of the aluminum or copper surface, aluminum-supported PCB is also famous. They have some benefits over fiberglass boards. Aluminum-backed PCBs are therefore particularly beneficial for high performance.

These benefits include: –

It has higher thermal efficiency and can quickly release heat from the circuit. Aluminum-backed PCBs cool down more rapidly than other PCBs. This type of board is beneficial for complicated projects due to thermal and heat dispersion improvements.

Furthermore, the higher durability and cheaper cost for sophisticated and heavy-duty performance. As a result, the aluminum-backed PCB outlasts the fiberglass PCB.

Double-sided PCB: –

Electronic components are located on both sides of the substrate, comparable to a single-sided PCB. Electronic components are embedded on double-sided boards using two methods: through-hole or surface mount technique. As a result, surface mount technology is the method of directly attaching the component to the board. In contrast, hand punching holes into the board and soldering the ingredients together is made by hand. Furthermore, the surface mount offers more duties, faster performance, and lower weight.

Rigid PCB: –

Rigid PCB is often manufactured on a solid substrate. The board’s flexibility and bending are reduced as a result. As a result, the component’s life span extends.

Conclusion: –

If you want to have a trusted PCB for your use, get yourself the best China PCB Manufacturer. When selecting a PCB manufacturer, seeking legitimate and trustworthy suppliers is critical. Don’t forget to have thorough research while choosing the best type of PCB and the best manufacturer. You never choose or buy a product without researching about it, never fall for any other companies tag line or any other things just check it and research it by your own then only go for it. It will save you from having bad quality products. So go and do research and then buy the most quality PCB for your use.